- Home

- »

- Custom Food Labels

Industrial Custom Food Labels for Zero Failure Packaging Performance

Stop risking your reputation on low-grade adhesives. Get industrial-strength labels precision-engineered for flawless performance and extreme moisture resistance—perfectly suited for artisanal hand-application or high-speed production lines.

✅ -20°C Cold-Temp Certified Reliability

✅ Pantone-Matched Color Consistency

✅ Anti-Flagging Advanced Adhesive Tech

Core Production Matrix for Every Application Scale

Select from battle-tested label formats precision-engineered to ensure flawless brand presentation across manual hand-application and high-speed industrial production environments.

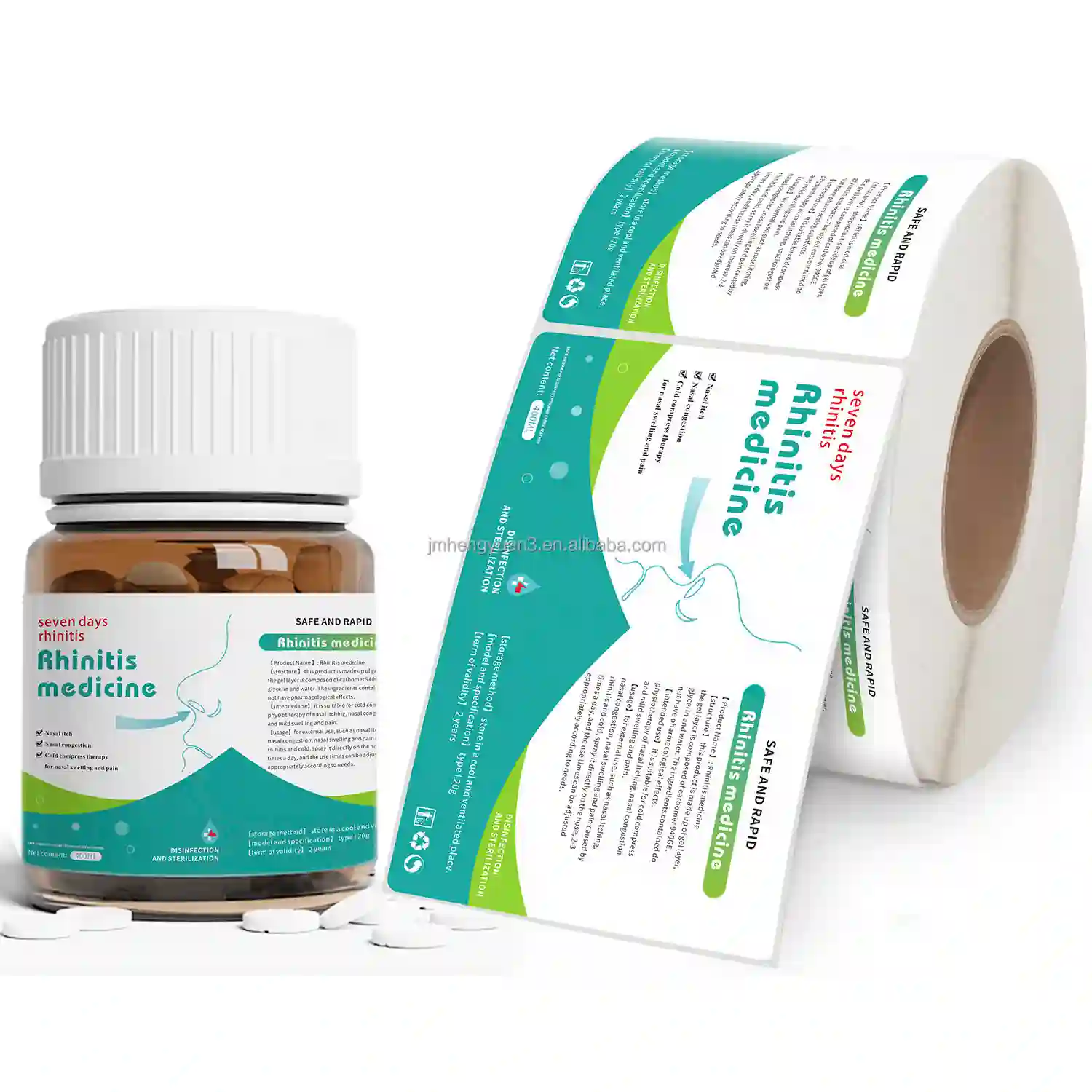

Custom Food Roll Labels

Precision-rewound rolls with custom unwind directions to ensure zero-jam performance on high-speed automated food packaging and bottling lines.

Waterproof BOPP Food Labels

Oil-resistant 2.4mil synthetic films that prevent edge-peeling and ink migration in high-humidity refrigeration and damp food storage environments.

Custom Frozen Food Labels

Specialized low-temperature adhesives maintaining 100% structural integrity in deep-freeze environments down to -40°F without losing adhesion or cracking.

FDA Compliant Food Labels

Food-grade materials and safe inks ensuring strict regulatory compliance for direct packaging contact, eliminating legal risks and safety recall anxieties.

Premium Quality Across Every Batch

A glimpse into our high-precision manufacturing—delivering boutique-level aesthetics with industrial-grade reliability for global brands.

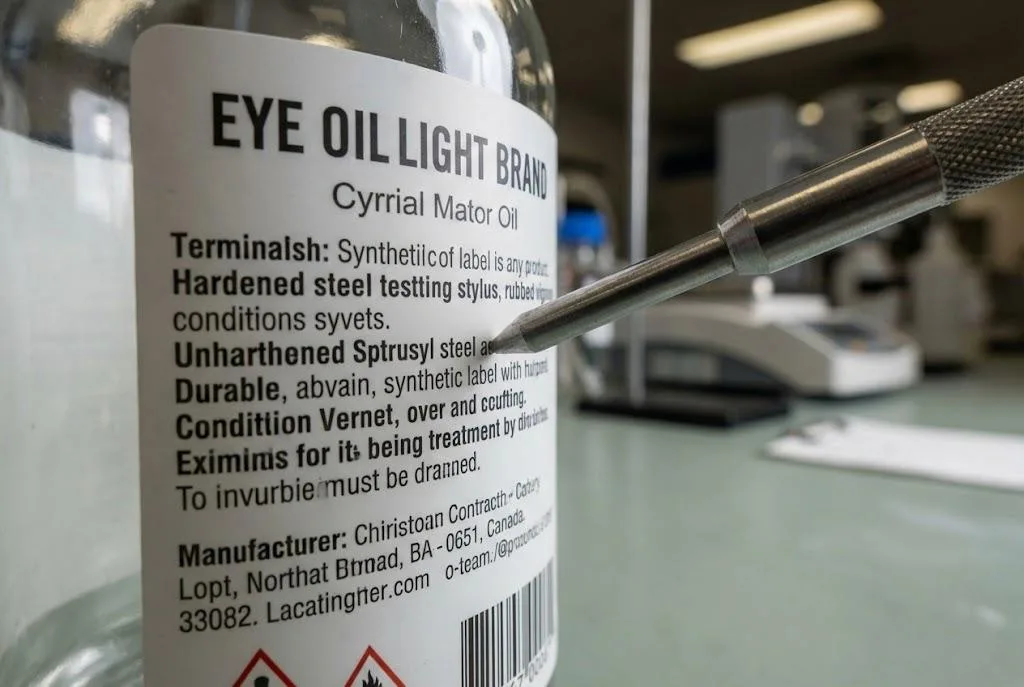

Battle Tested Performance Lab for Extreme Reliability

Every material undergoes a rigorous series of stress tests under simulated extreme conditions to guarantee zero physical failure and absolute brand integrity throughout the entire product lifecycle from initial transit to the final retail display.

The 48H Ice Bucket Challenge

Submerged in ice water for 48 hours, our proprietary adhesive maintains 100% bond strength without edge lifting or ink bleeding.

High-Speed Scuff Resistance Test

Reinforced UV lamination protects graphics from abrasive friction during long-haul shipping and frequent consumer handling on grocery shelves.

Market Ready Integrity from Flash Freeze to Retail Shelf

Labels carry more than a brand; they must survive rigorous food supply chain conditions while maintaining absolute regulatory legibility and physical bond.

Cold Chain Surviva

Engineered to withstand the "sweat period" when products transition from cold storage to ambient temperatures, ensuring zero edge-lifting or adhesive failure.

Regulatory Precision and Trust

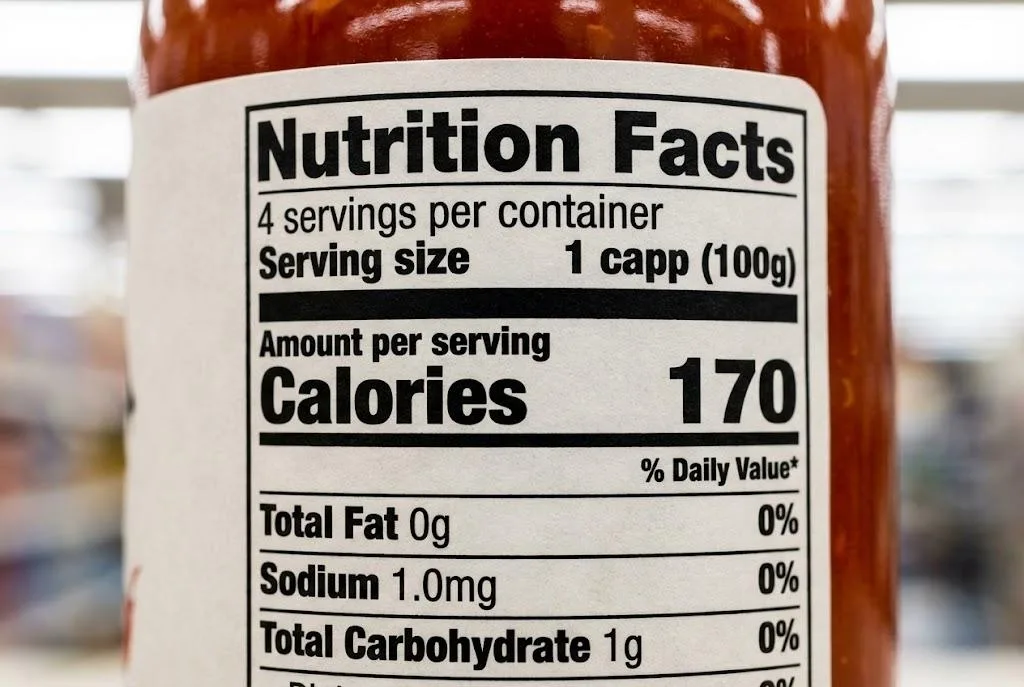

High-density ink technology ensures complex FDA nutrition panels and fine-print ingredient lists remain crisp and scan-ready to prevent costly retail rejections.

High Performance Label Engineering and Strategic Selection Logic

Every food product requires a specific balance of tactile brand appeal and industrial environmental resistance to ensure zero failure from production to consumer.

Textured Estate Paper vs Synthetic White BOPP

- Artisan Texture (Estate Paper) — Best for premium jars like honey or wine. The tactile grain establishes an organic connection and justifies a higher price point.

- Industrial Precision (BOPP) — Best for high-use condiments and oils. This non-porous film is naturally waterproof and smudge-proof for maximum retail durability.

UV Varnish vs. Heavy-Duty Lamination

- (Left): UV Varnish (Cost Efficient) — A liquid coating for pantry-stable goods. It prevents ink scuffing at a lower unit cost while maintaining fast application speeds.

- (Right): Film Lamination (Total Immunity) — A physical PET barrier essential for cold-chain products. It prevents peeling when moving from frozen storage to humid room temperatures.

Engineering Standards & Specifications

| Base Material | Premium White / Clear / Silver BOPP (2.4 mil) |

|---|---|

| Adhesive Type | All-Temperature Permanent Acrylic (FDA 175.105 Compliant) |

| Minimum Application Temp | -10°F (-23°C) for frozen environment reliability |

| Service Temp Range | -65°F to +200°F (-54°C to 93°C) |

| Print Technology | HP Indigo Digital / Flexographic (Pantone Color Match) |

| Release Liner | 40# White Glassine or PET liner for high-speed stripping |

| Standard Core Size | 3" ID (Customizable 1" or 1.5" for manual dispensers) |

| Dimensional Tolerance | ± 0.0156" (0.4mm) for precision machine alignment |

Verified Performance from the Front Lines

Direct feedback from the packaging specialists and brand owners who trust our engineering to secure their supply chain integrity and retail success.

Have a Question?

FAQ

Common Questions About Custom Sheet Labels Printing

Which material is best for high-moisture glass containers?

- glass with condensation, we recommend White BOPP with a permanent acrylic adhesive to ensure zero flagging.

- Can your labels withstand deep-freeze storage? Yes, our Cold-Temp Adhesive is specifically

Can your labels withstand deep-freeze storage?

How do I determine the correct unwind direction for my applicator?

Are your inks and materials FDA compliant?

What is the lead time for high-volume wholesale orders?

Do you offer custom die-cut shapes for unique bottle designs?

Secure Your Production Integrity Today

Stop letting labeling inconsistencies derail your schedule.

Partner with a technical team dedicated to zero-defect execution and seamless shelf performance for your next production run.

12h Expert Response

Free Pre-Press Audit

Direct Factory Pricing

Get Your Factory-Direct Quote

Response within 12 hours. Save up to 30% on bulk orders.

🔒 100% Privacy. No Hidden Costs. Free Sample Options.